Mimaki TxF300-75 DTF Printer

This new TxF300-75 has been shown to increase productivity by 300% compared to the existing model, further setting Mimaki apart as a leader in textile and apparel printing solutions.

Embodying the same core functionalities as the TxF150-75, the TxF300-75 promises safe and stable operation while increasing productivity.

Integral features for seamless operations include:

Degassed Ink Pack: Eliminate air from entering through to the ink supply to the print head, thereby preventing nozzle drop out and ensuring constant high image quality.

New White Ink Circulation Technology (MCTv2): Prevents white ink sedimentation by continuously circulating the ink all the way to the damper above the print head for continuous high-quality production.

3-Way Intelligent Heater: Pre- and print heaters control the spread of ink on the media for blur free image quality and post heater accelerates drying of ink.

New Pinch Roller System: Fine-tuned pressure of pinch rollers enabling stable DTF film feeding.

Nozzle Check Unit (NCU): Automatically checks and detects clogged nozzles and starts cleaning function to recover them.

Nozzle Recovery System (NRS): When Nozzle Check Unit (NCU) cannot recover clogged nozzle by cleaning function, the Nozzle Recovery System (NRS) automatically substitutes defective nozzles with working ones to ensure constant image quality and uninterrupted production.

OEKO-TEX® ECO PASSPORT Certification: PHT50 thermal pigment inks are OEKO-TEX® certified. Ensuring the inks are free from any chemicals that could be harmful to human health. PHT50 inks are suitable to print skin-friendly clothing and other textiles for end users.

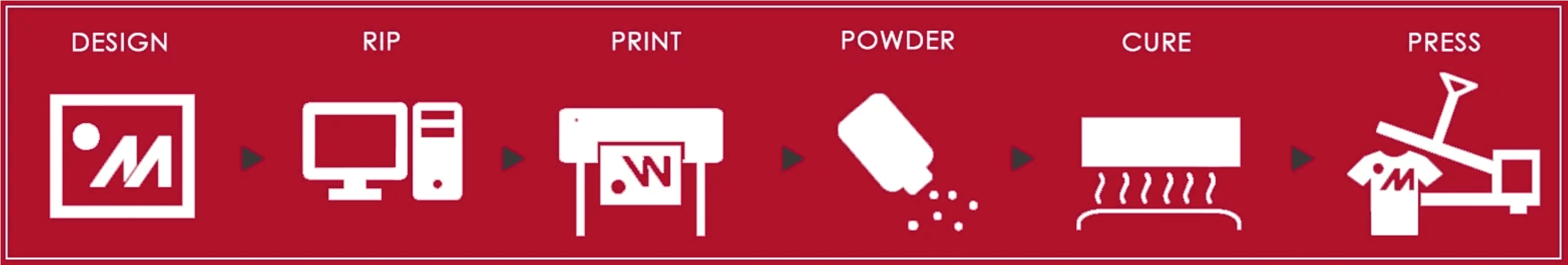

What is DTF?

DTF or “Direct To Film”, is a printing method in which a printer directly outputs onto a special film called DTF film, applies a powder called hot-melt powder, and then applies heat to dry it. The resulting transfer sheet can then be heat-pressed on fabrics.

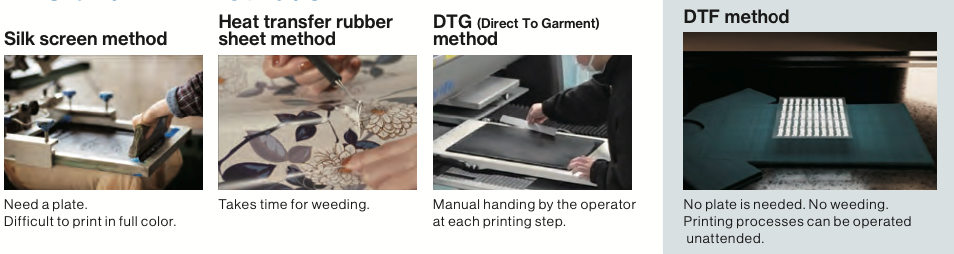

Comparison of Silk Screen, Heat Transfer DTG and DTF Methods

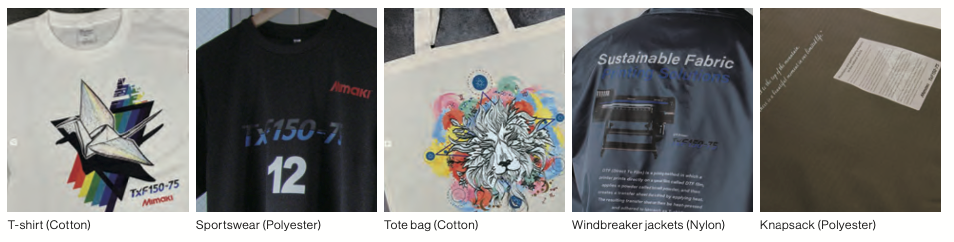

Possible Uses

Decorate various fabrics using one DTF system...

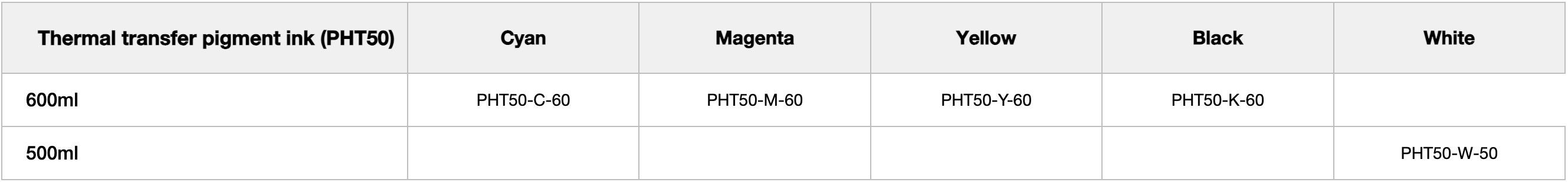

Inks