How To Use DTG

Direct To Garment (DTG) application is a process of printing straight onto textiles and garments using specialised technology. Here's a quick guide to this fantastic method...

1. When printing black or dark garments white ink is needed. Therefore the garment will need to be pre-treated to prevent the white ink from penetrating the fabric. This can be applied using a pre-treatment machine or by hand.

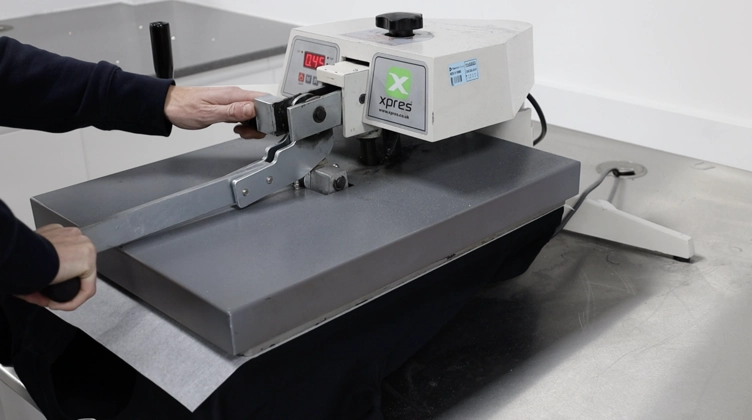

2. The pre-treatment then needs to be dried. This can be done using a tunnel dryer, an oven dryer or on a heat press. We always recommend pressing the garment before printing to flatten down any fibres on the garment.

3. Once dried, load the garment onto the platen of the DTG printer, making sure it is flat. Select the design and the settings required for the garment type and set to print.

4. When printing is finished, carefully take the garment off the platen. the inks now need to be cured and this can be done using a heat press, tunnel dryer or drying oven.

5. Your garment is complete.

Speedy and efficient

No minimum orders

Minimal setup time and cost

Ideal for online selling

Whole design printed in one run through the printer

No limitation on number of colours involved

Environmentally friendly

Excellent detail on designs with long lasting results

1. What can I DTG print onto?

We recommend that you print using DTG onto garments that are either 100% cotton or have cotton print face, specifically designed for DTG, such as our range here.

2. Do I need to do anything to the garments before printing?

If you are printing with just CMYK then mostly no. However, if you are printing using white ink or printing onto polyester, then you will need to pre-treat the garment first.

3. What equipment is required?

-

Computer or tablet for designing

- Heat press or curing unit

4. Can you easily maintain a DTG Printer?

Maintenance, pre-treatment and curing garments are all extremely easy with the best DTG printers on the market.