How To Sublimate Cushions

With customers set to spend £1 billion on personalised gifts over the next 12 months, is now the time to take advantage? What better way than by offering the simple yet effective printed cushion? Take a look at our guide to sublimating cushions below...

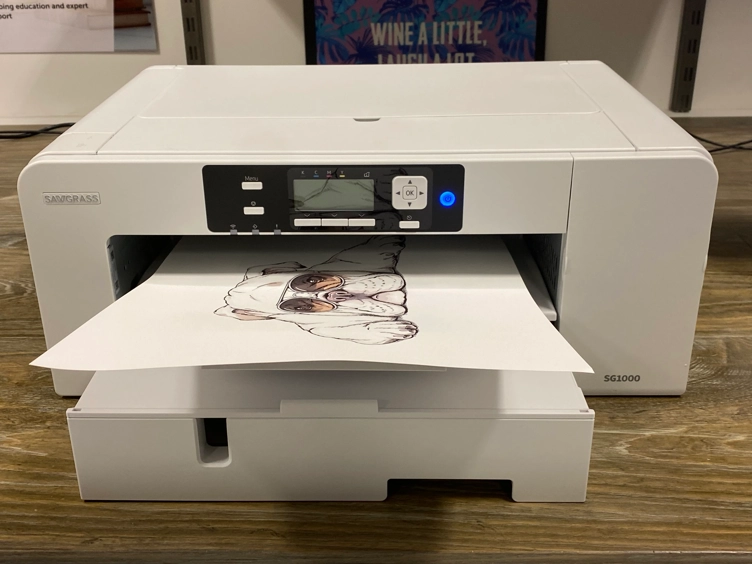

1. Create your design and print in mirror.

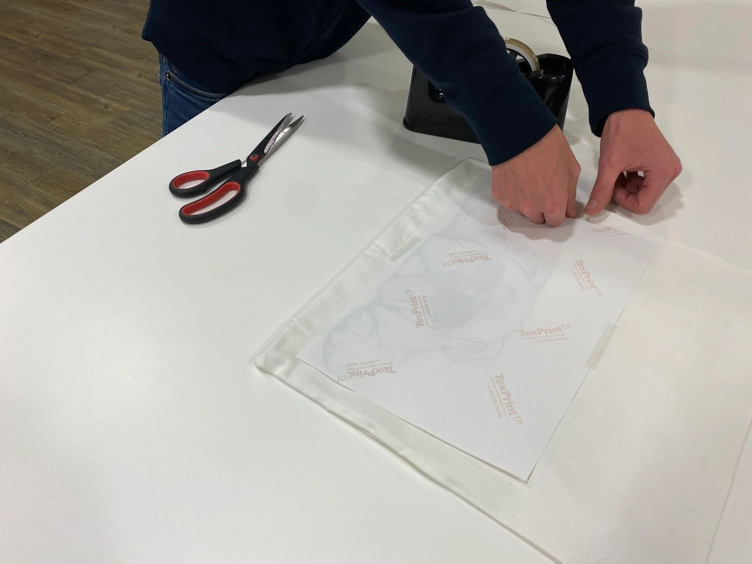

2. Cut a square of silicone paper slightly smaller than the cushion and insert inside, keeping it as flat as possible. This is to avoid printing through the cushion onto the back.

3. Cut loosely around the design.

4. Place your design onto the cushion and secure in place with heat tape.

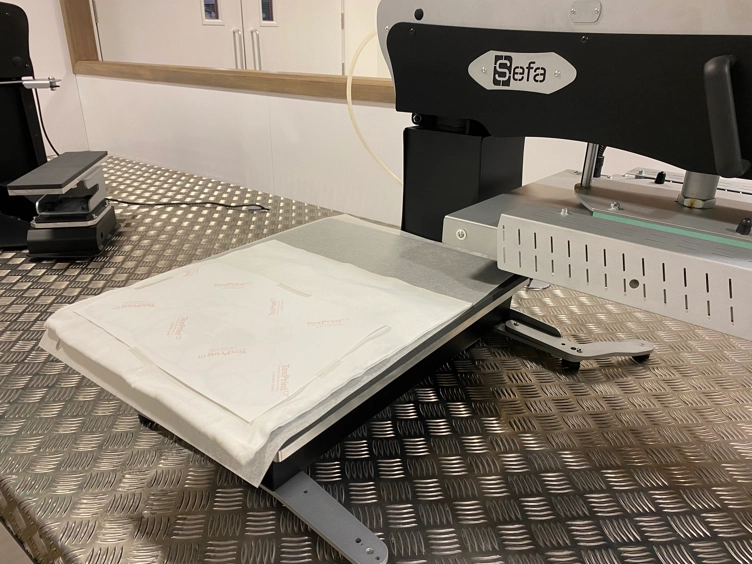

5. Place the cushion on the heat press with the transfer paper on the top and cover with a silicone sheet. Try and avoid pressing the zip. Press at 200°C for 60-80 seconds using a light/medium pressure.

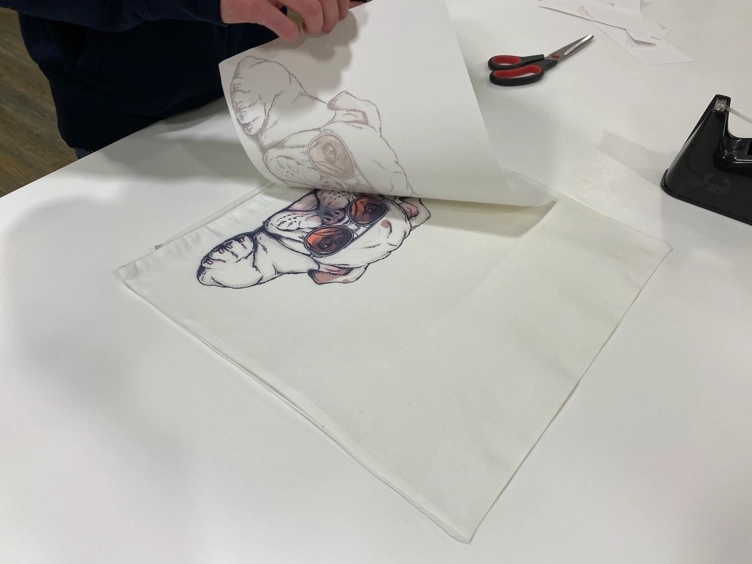

6. Once cooled down, remove the silicone sheet from inside the cushion and insert cushion inner (sold separately).

Speedy and efficient

Ideal for smaller batch orders

Excellent results with more complicated designs, giving you more freedom

Allows you to choose a design that can cover the vast majority of your product

Designs don’t crack, peel or fade

1. What can I sublimate onto?

Garments with a polyester or a polyester mix fabric or various blanks with a special polymer coating (such as our mugs and coasters).

2. What equipment is required for sublimation?

- Heat press (for mugs, a specific mug press is required)

- Computer or tablet for designing

3. Why can’t I sublimate on dark garments?

It isn't possible to sublimate on dark coloured garments because there is no white sublimation ink.

4. Why does the image on my screen differ to the final printed result?

It is entirely possible for a print from a sublimation printer to look different to the image on your computer screen. This is because sublimation inks often change colour during the heat pressing process. As the ink reacts when it is heated, it sometimes becomes brighter and more vibrant than the image printed on the sublimation paper. We would highly recommend that, during your testing stage, you heat press the image on to a product to see the final result before beginning a batch order.

5. Can I use an iron instead of a heat press?

No. You need a continuous, even heat and pressure to be applied simultaneously to the entire surface area. This can only be effectively achieved using a heat press.